You asked, we answered: How important is AI for gold demand?

21 November, 2024

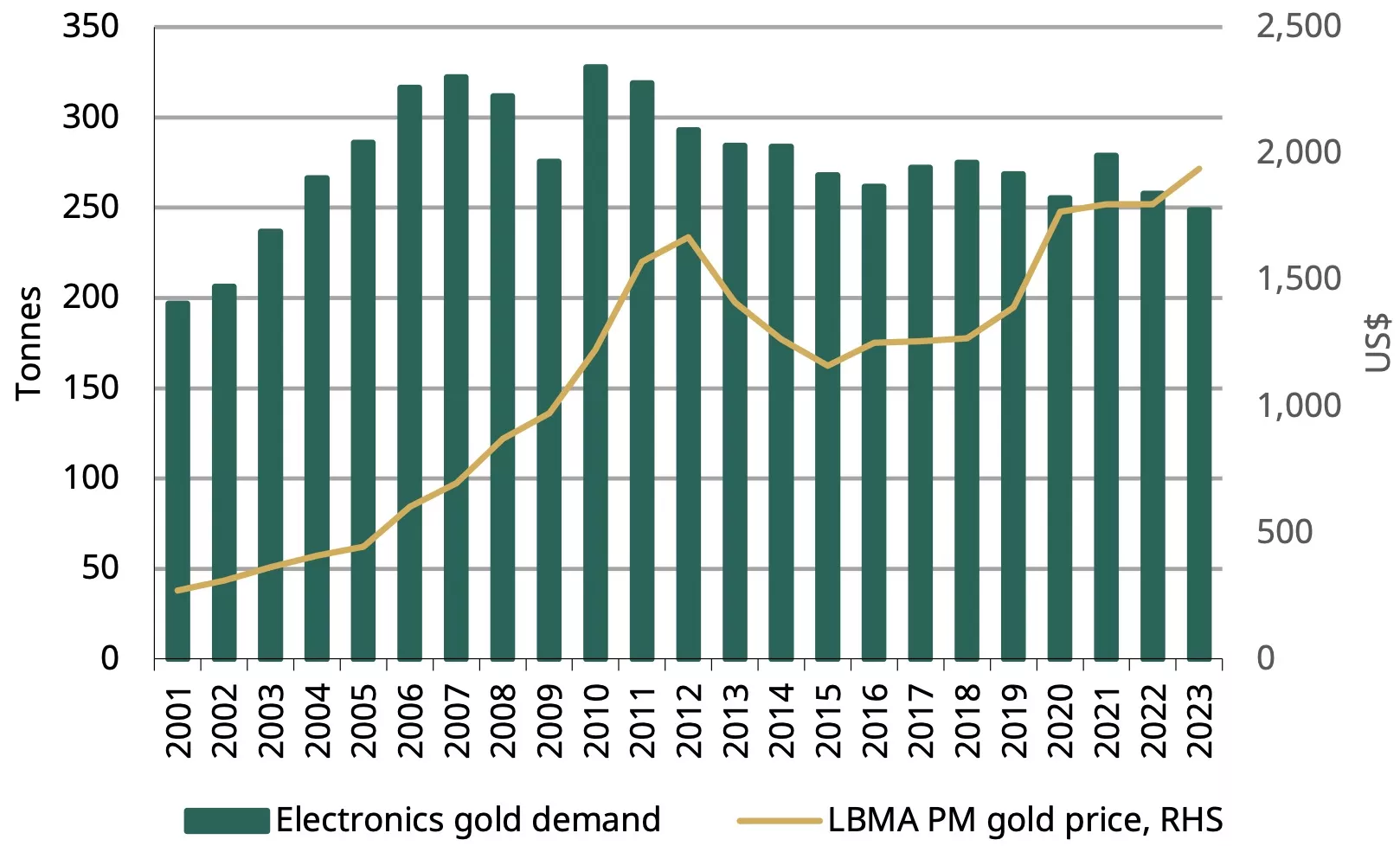

Demand for gold used in electronics peaked in 2010 at 328t, steadily falling to 249t in 2023. In recent quarters, however, this sector has seen a modest recovery. And we’ve received a raft of questions around how much of that recovery can be explained by the growth of Artificial Intelligence, whether it will continue to drive growth in the sector and why exactly AI is an important emerging area of demand for gold.

Gold in electronics: a recent history

Gold plays a crucial role in electronic devices: it is an excellent conductor of electricity; it does not corrode; and its physical and chemical properties allow it to be manipulated into extraordinarily thin wires and reliable coatings. These properties make it an indispensable component of the computer chips found in almost all electronic equipment.

The surging price of gold between 2001 and 2011 (from ~US$250/oz to over US$1,800/oz) encouraged manufacturers in the electronics industry to look for ways to reduce their gold usage. These strategies involved both substitution (replacing gold with alternatives such as silver and copper) and thrifting (using smaller and smaller quantities of gold).1

Chart 1: Manufacturers reduced gold usage in response to the price rise

Gold used in electronics, in tonnes, and the annual average gold price, in US$/oz*

*Data as at 30 September 2024.

Source: ICE Benchmark Administration, Metals Focus, Refinitiv GFMS, World Gold Council

But retooling and process development does not happen overnight in electronics fabrication facilities; indeed, it is a multi-year process. And this shift coincided with consumer demand for ever more powerful, functional and reliable devices powered by advanced electronics and increasingly complex chips – think the proliferation of now-ubiquitous smartphones and the vast growth in laptops, smart TVs, electric vehicles…the list goes on. Manufacturers had to balance cost reduction with gold’s indispensable role as they addressed the growing need for high-end, durable components during this unprecedented period of “electrification”.

The role of gold in AI

AI is fast becoming a cornerstone of modern technology, driving advancements across various industries. The considerable electronics infrastructure required to power this rapidly growing sector has a direct impact on industrial gold demand.

As outlined above, gold is an essential component in the manufacturing of AI-enabled devices. AI systems rely heavily on advanced hardware, including processors, memory chips and sensors, all of which utilise gold. AI-enabled devices, such as smartphones and autonomous vehicles, alongside a corresponding growth in data centres, has created an exponential rise in the need for highly efficient and reliable electronic components. Gold's superior conductivity ensures that data can be processed and transmitted at high speed with minimal energy loss. Furthermore, gold's resistance to corrosion ensures component longevity and durability – critical for continuous and intensive AI applications.

As AI technology advances, the demand for more sophisticated and powerful hardware can only increase. This, in turn, is likely to drive demand for gold, as manufacturers seek to enhance the performance and reliability of their AI-enabled devices. Meanwhile, sectors such as healthcare and finance are looking to AI in order to improve efficiency and innovation, and this can only further amplify demand.

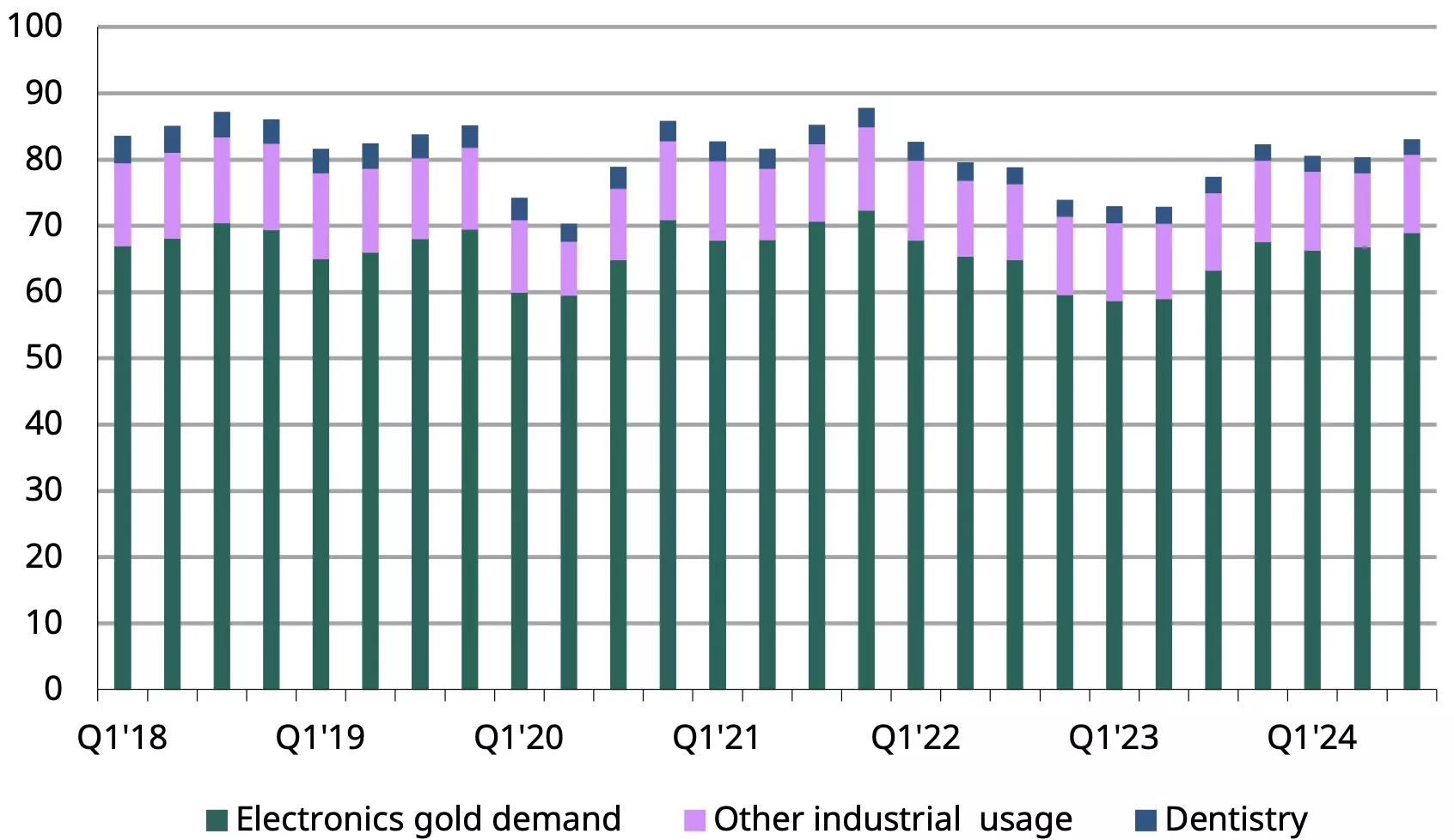

Chart 2: AI-proliferation has aided the recent recovery in gold usage

Gold used in technology applications, in tonnes, and the quarterly average gold price, in US$/oz*

*Data as at 30 September 2024

Source: ICE Benchmark Administration, Metals Focus, World Gold Council

But once again manufacturers face the challenge that catalysed the earlier wave of gold substitution and thrifting: cost. With gold recently reaching all-time highs of over US$2,700/oz, manufacturers are bound to face renewed pressure to evaluate how they use gold. But the situation today is very different to that of 2010 in that most of the “easy” thrifting and substitution has already been implemented; there is a limit to how thin wires and coatings can be and it is highly likely that they are already close to – if not at – that point. Additionally, as technologies evolve, some of gold’s traditional uses may slowly wane; one example is the ongoing changes in the LED sector where gold-free mini-LEDs are slowly usurping the gold-containing incumbents.

So what does this mean for the future of gold demand in the technology sector?

Gold's role beyond AI

While the electronics industry still dominates demand for gold in the technology sector, it is far from the only application that relies on this precious metal. Gold's versatility and unique properties make it indispensable in various other areas of technology:

- Medical devices: gold is used in many therapeutic devices, such as implants, where it is valued for its biocompatibility and resistance to bacterial colonisation. Gold nanoparticles are also critical in the medical diagnostics field and are being trialled as potential drug delivery devices.

- Aerospace: gold is used in the production of critical components for satellites and spacecraft. Its ability to withstand extreme temperatures and its reflective properties make it ideal for protecting sensitive equipment from radiation and heat.

- Clean technologies: gold is an excellent chemical catalyst and a promising candidate material in the production of clean hydrogen and carbon dioxide transformation.

In conclusion, gold will continue to be a critical component in the electronics industry, with AI applications bolstering its demand in the near term. But in this cost-driven sector manufacturers will continue to innovate and this will inevitably impact how gold is used in certain applications. Beyond electronics, gold’s unique properties make it a valuable resource across multiple areas, ensuring its continued relevance in the ever-evolving technology landscape.

1Substitution occurred almost entirely at the lower end of the market, especially where safety or device longevity was less of a consideration (neither silver nor copper are corrosion resistant, making failure more likely). Thrifting was more widespread across the industry, facilitated by thinner gold wires and coatings, and by a more careful management of gold usage during the manufacturing process.